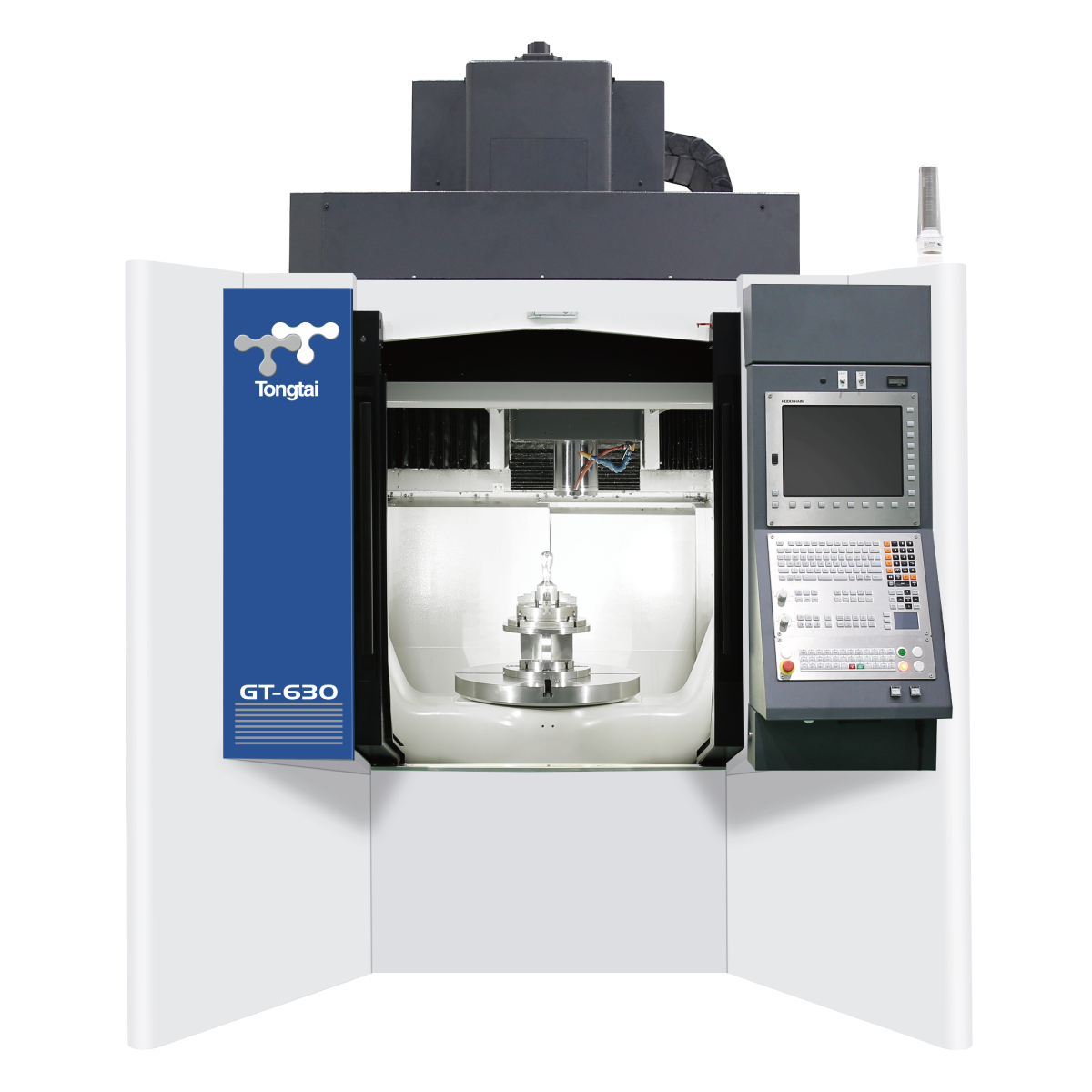

5-axis Machining Center GT Series

TONGTAI MACHINE & TOOL CO., LTD.

GT Series is the gantry type structure, the control of three linear axes, wihch are free from affect of workpiece weight, and the driven centers of three axes are all on these gravity center. It significantly improves dynamic stability. It is developed for aerospace, mold, and automotive parts machining. 15K/20K/24K rpm spindle are both available for selection. GT Series could install our Tongtai TIMS , it has the diverse intelligent APP to help customer to increase product performance and quality. For production line, it could install TLM software. The factory data could be visualized, find and solve the problem, increase the production performance, predictive Maintenance and to avoid shutdown without warning.

GT Series is the gantry type structure, the control of three linear axes, wihch are free from affect of workpiece weight, and the driven centers of three axes are all on these gravity center. It significantly improves dynamic stability. It is developed for aerospace, mold, and automotive parts machining. 15K/20K/24K rpm spindle are both available for selection. GT Series could install our Tongtai TIMS , it has the diverse intelligent APP to help customer to increase product performance and quality. For production line, it could install TLM software. The factory data could be visualized, find and solve the problem, increase the production performance, predictive Maintenance and to avoid shutdown without warning.