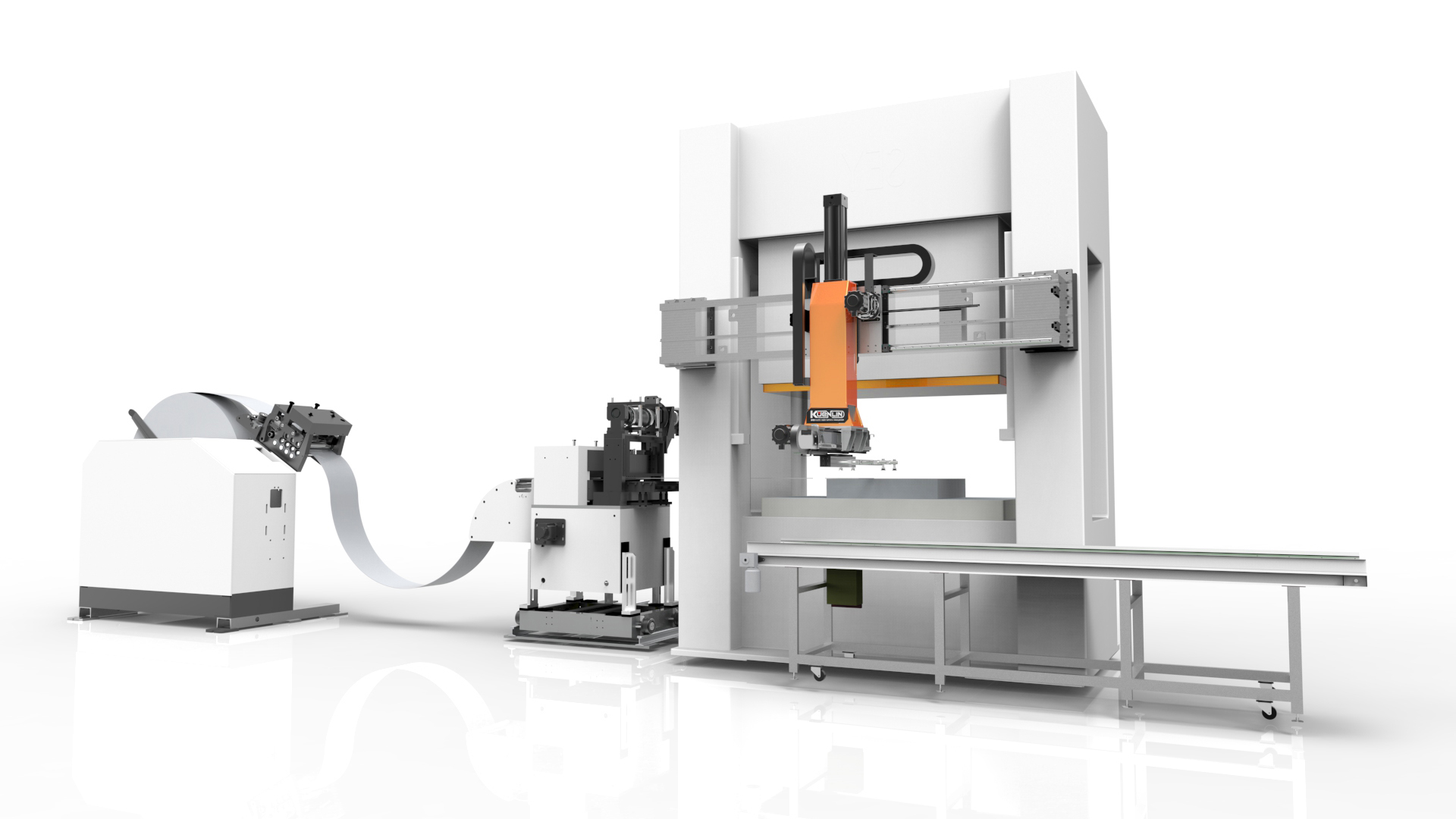

Linear Robot Feeder

KUEN LIN PRECISION CO., LTD.

Construction of a linear transfer module is to pursue automation professionalism with better flexibility and coordination. Combining the mechanical technology used by KSF-3R, we can provide optimized automation applications where many different specifications used in the stamping field can also be worked with.

●High-rigidity transfer structure

●Fast transmission for high transfer efficiency

●Transfer with high precision and accuracy loop

●Equipped with Japanese-made Yaskawa absolute value servo motor

●MPG manual simulation device

●Free path editing

●Quick fixture replacement (automatic coupling device available)

●Can adopt robot leader communication mode

●Multi-axis synchronous control, using Yaskawa communication mode driver

●Human-machine free I/O setting, electromagnetic valve time modification autonomy

●With insulation fixture, it can be used for hot stamping multiple production mode (1 mold for 1-4 parts)

●Equipped with centering device to ensure correct feeding angle and action coordination.