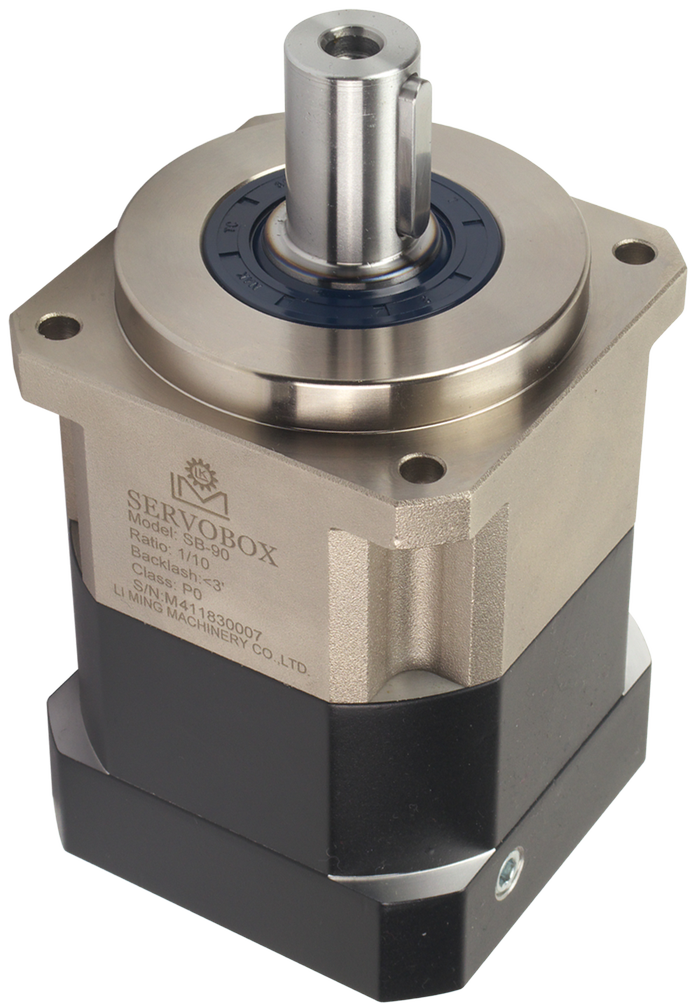

Liming Precision Planetary Reducers

LI MING MACHINERY CO., LTD.

SERVOBOX series high precision planetary gear reducer employs helical gears.All gears are high precision machined by CNC gear hobbing machine, providing high accuracy gear engagement, smooth running and minimum noise.

SERVOBOX series high precision planetary gear reducer employs helical gears.All gears are high precision machined by CNC gear hobbing machine, providing high accuracy gear engagement, smooth running and minimum noise. LIMING gear box is one-piece fabricated. When comparing with the competitive gear reducer, LIMING gear reducer features smaller construction (saves over 1/4 of size and weight), higher output torque and higher transmission efficiency.