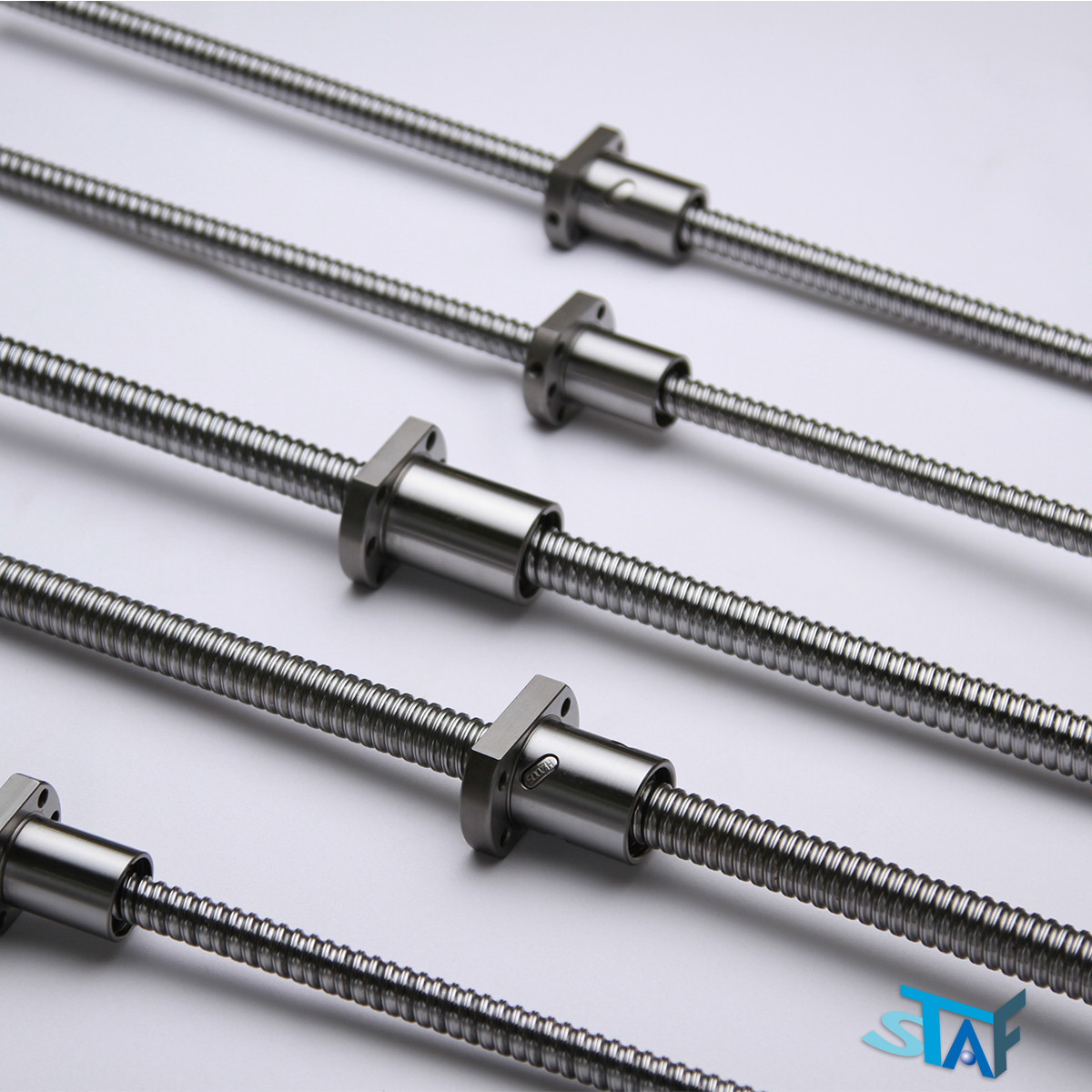

FSU / FDU / FDI / FSI / FSB / FSS / RSU / RSH / FSK / RSK / RSY / FSE Series

OME TECHNOLOGY CO., LTD.

Rolling ball bearings within a ball screw can make the internal friction lower, so the ball screws can offer a high level of efficiency and positional accuracy even at high torque and force loadings.

We offer a complete selection of Ball Screws that suited to machine tools, injection molding machines, and general machinery as well as for use under special environments, such as semiconductor and LCD production equipment.

●Internal Circulation Series:The internal circulation design can save more space. Suitable for machines with small internal space, general machine tools, general industrial machines, and automation machines.

●Cylindrical Series:No flange design and save space, No gap, High rigidity. Suitable for Automotive and welding, Semiconductor industry, Woodworking machinery, Industrial automation applications.

●Low Voice Series:Quiet, high speed and miniaturization. It can achieve the ""quiet'' effect for all kinds of use needs, from conveying purposes to working machinery. Low noise and good sound quality. Suitable for Semiconductor equipment, measuring equipment, industrial equipment.

●DIN 69051 Series:High precision, low noise, smooth behavior, in line with JIS (and DIN) standards. Suitable for Automotive and welding, Semiconductor industry, Woodworking machinery, Industrial automation applications.

●High Lead & Super High Lead Series:High speed, High rigidity, Lower noise. Suitable for machine tools, cutting machines, industrial machines.

●Miniature Series:Inner loop design, Small space and light weight, High positioning accuracy, Especially suitable for small lead. Suitable for Semiconductor equipment, measuring equipment, inspection equipment.