◆ S-Curve flexible acceleration and deceleration control is adopted to achieve high speed and smooth movement.

◆ Advanced AC servo drive system for all axes.

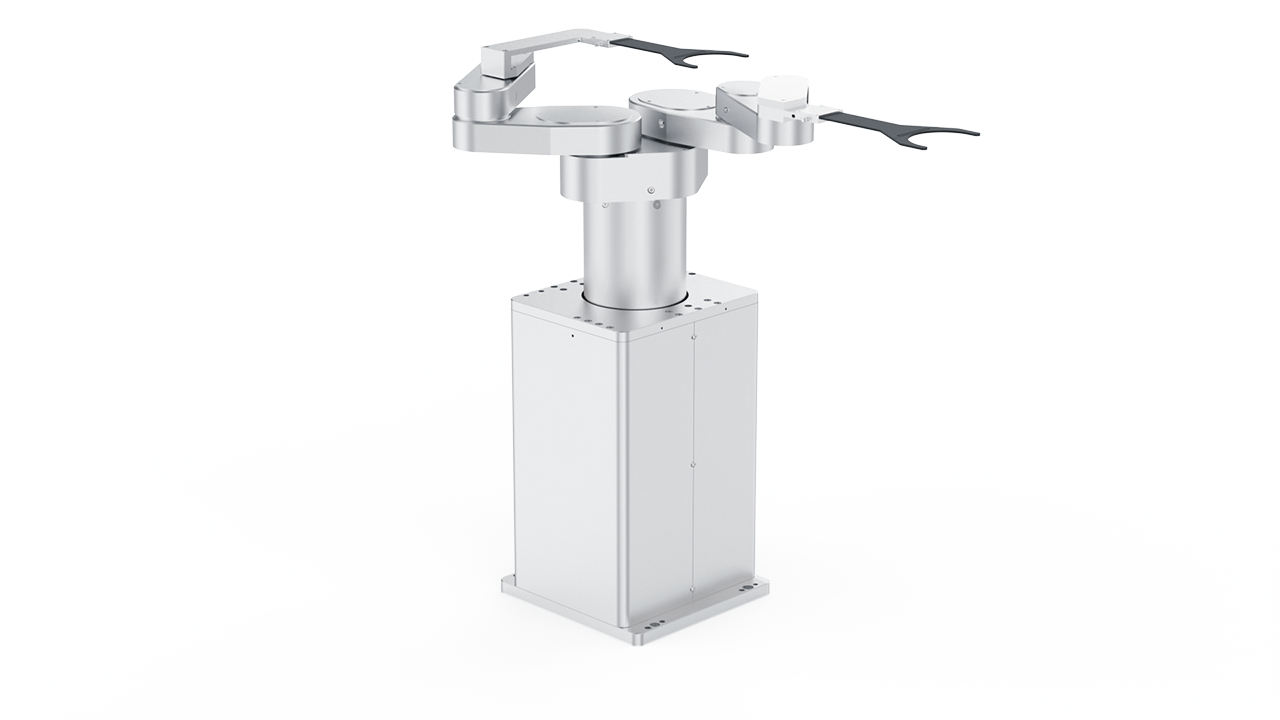

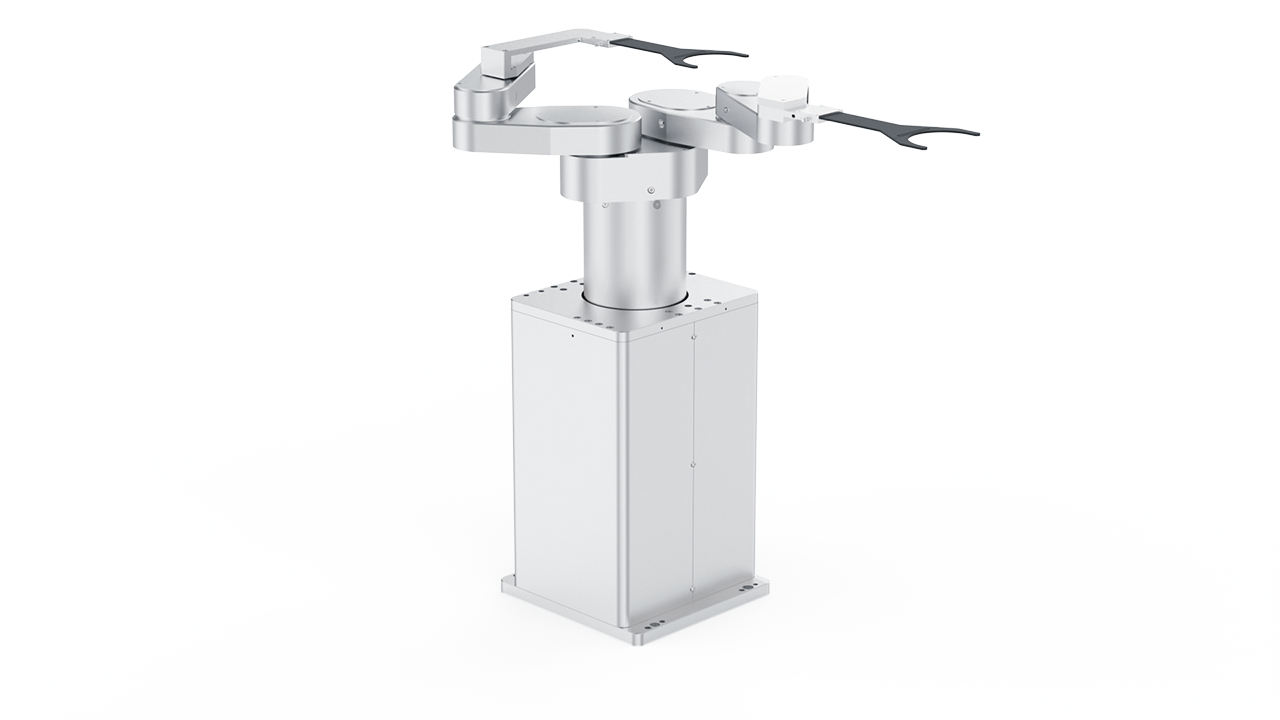

◆ Dual-arm design increases wafer throughput.

◆ Vacuum and edge-grip end-effector options are available.

◆ Wafer mapping (optional).

Operating Rang of Z Axis

300/350/500 mm

Operating Rang θ Axis

340°

Operating Rang R/L Axis(Arm)

410/515/615mm

Speed of Z

Maximum 400mm/s;Mean Time 1.17 s/350mm

Speed of θ

Maximum 300°/s ; Mean Time1.90s/340°

Speed of R/L Axis(Arm)

Maximum 1090/1340/1675 mm/s; Mean Time 0.7s 385/475/595mm

Power

220VAC,50Hz/60Hz,1PH,11A

Payload Capacity

Below 3 kgf